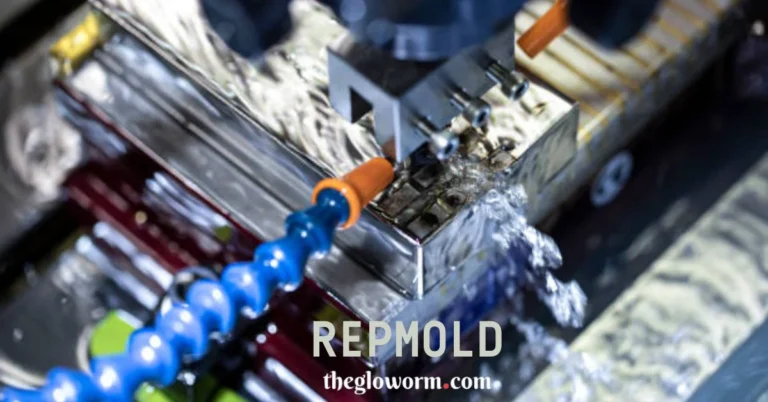

Introduction to Repmold

Welcome to the future of manufacturing, where precision meets efficiency like never before. Enter Repmold—an innovative solution that’s transforming how products are created and delivered. With a focus on automation and streamlined processes, Repmold is not just another tool; it’s a game changer for manufacturers across various industries. As we dive deeper into what makes Repmold unique, you’ll discover how it stands apart from traditional methods and why businesses of all sizes should consider making the switch. Get ready to explore the exciting world of automated manufacturing!

The Traditional Manufacturing Process vs. Repmold’s Automated System

Traditional manufacturing often relies on manual labor, involving significant time and resource investment. Workers must meticulously handle every aspect of production. This process can lead to inconsistencies in quality and increased overhead costs.

In contrast, Repmold leverages advanced automation technology. With its precision-driven systems, it eliminates much of the human error that plagues traditional methods. The result is a more streamlined workflow that not only saves time but also enhances product accuracy.

Manufacturers using Repmold can expect faster turnaround times without sacrificing quality. Automation simplifies complex tasks, allowing for quicker adjustments based on real-time data feedback.

This shift towards an automated system means greater scalability for businesses looking to expand their operations efficiently. It’s a transformative approach that modernizes how products are created, offering adaptability in an ever-evolving market landscape.

Benefits of Using Repmold for Manufacturers

Repmold brings a wealth of advantages to manufacturers eager for growth. Its automated system streamlines operations, drastically reducing production times. This streamlined process enables businesses to hit strict deadlines while maintaining high-quality standards.

Cost savings are another significant benefit. By minimizing waste and optimizing resource use, Repmold helps businesses lower their operating expenses. Manufacturers can reinvest these savings into innovation or expansion efforts.

Flexibility is key in today’s market, and Repmold excels here as well. The platform adapts seamlessly to various projects, making it suitable for small batches or large-scale productions alike.

Moreover, the precision offered by Repmold ensures consistent product quality, fostering customer trust and satisfaction. With each piece manufactured accurately, brands build a reputation for excellence that stands out in competitive industries.

Embracing RepMold enables manufacturers to focus on what truly matters: enhancing creativity and driving business success.

How Repmold is Changing the Game for Small Businesses

Repmold is a game-changer for small businesses, transforming the way they approach manufacturing. With its automated system, it streamlines production processes that were once labor-intensive and costly.

Small enterprises can now access advanced technology that was previously reserved for larger corporations. This levels the playing field in competitive markets.

The user-friendly interface allows entrepreneurs to design and modify products efficiently. They can respond quickly to customer demands without compromising quality.

Moreover, Repmold minimizes waste through precise material usage, which is crucial for budget-conscious businesses. The reduction in lead times enhances overall productivity.

Incorporating Repmold into their operations enables small manufacturers to innovate confidently, opening doors to new opportunities and growth potential.

Case Studies: Real-Life Examples of Repmold in Action

One notable example of Repmold in action comes from a small automotive parts manufacturer. After integrating Repmold’s system, they reported a 30% increase in production speed. This efficiency gain allowed them to meet tight deadlines without sacrificing quality.

Another case involved a startup focused on consumer electronics. By utilizing Repmold’s automated processes, they reduced material waste significantly. Their ability to produce high-quality prototypes quickly led to faster market entry and enhanced competitiveness.

A textile company also embraced the power of Repmold. They streamlined their fabric cutting process, minimizing errors and maximizing precision. As a result, not only did their output improve, but employee satisfaction rose as well due to less manual labor stress.

These examples highlight how diverse industries harness the capabilities of Repmold to transform operations and drive growth effectively. Each story showcases unique challenges met with innovative solutions that redefine manufacturing standards today.

The Future of Manufacturing with Repmold

The future of manufacturing is on the brink of a transformation, and Repmold is leading the charge. With its cutting-edge automated systems, this technology paves the way for unprecedented efficiency.

Imagine a landscape where production lines operate seamlessly. Machines communicate with each other in real-time, adjusting their processes to optimize output. This level of coordination minimizes waste and elevates quality control.

As industries embrace smart manufacturing techniques powered by Repmold, we can expect faster turnaround times and reduced costs. Small businesses gain access to advanced tools that were once reserved for larger corporations.

Moreover, sustainability takes center stage. By streamlining operations and using resources more judiciously, manufacturers can significantly lower their environmental impact. The combination of precision engineering with eco-friendly practices sets a new standard in the sector.

With innovation at its core, Repmold shapes not just products but also the very fabric of how we think about manufacturing’s role in modern society.

Conclusion

Repmold is set to transform the landscape of manufacturing as we know it. By incorporating automation and precision into every step, it streamlines processes that were once time-consuming and labor-intensive. Manufacturers are seeing not just increased efficiency but also significant cost savings.

Small businesses benefit immensely from Repmold’s innovative approach. They can now compete with larger enterprises by leveraging high-quality production without extensive investment in traditional machinery. This opens new doors for growth and scalability.

Real-life case studies demonstrate how companies have successfully integrated Repmold into their operations, showcasing impressive results in quality and turnaround times. The feedback underscores a shift towards more intelligent manufacturing solutions that cater to evolving market demands.

As we look ahead, the future of manufacturing appears bright with Repmold leading the charge. Its commitment to innovation promises a landscape where speed meets accuracy, redefining productivity across sectors.

Manufacturers who embrace this technology will not only thrive but also play a crucial role in shaping an efficient industrial future that prioritizes both quality and sustainability.