Introduction: The Tiny Brain Behind the Glow

Imagine driving through a foggy night in your iconic Mini Cooper. As your fingers brush over the dashboard, the interior glows with a subtle, calculated light—comforting, aesthetic, and precise. But behind that glow lies a hidden hero: the Mini Cooper backlight circuit board.

Much like the human brain silently orchestrates every movement and emotion, this circuit board operates in the shadows—directing light, enabling control, and enhancing the experience of driving a Mini Cooper. It’s not just about lights; it’s about intelligent design, technological synergy, and the fusion of function and form.

In this article, we dive deep into this often-overlooked component—unpacking its definition, evolution, significance across industries, and what it might mean for the future of automotive technology.

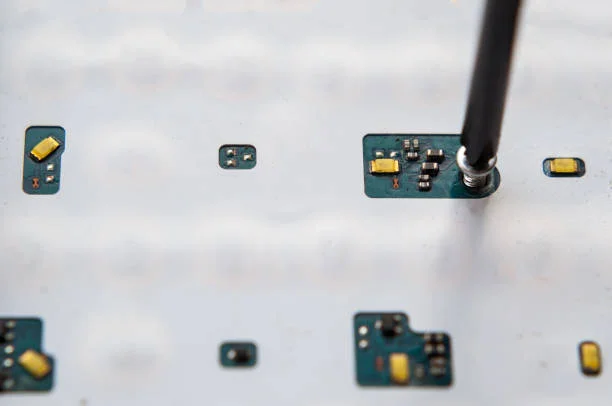

What is the Mini Cooper Backlight Circuit Board?

At its core, the Mini Cooper backlight circuit board is a printed circuit board (PCB) embedded within the dashboard or control interface of the vehicle. Its primary function is to power and control the illumination of buttons, dials, and screens—especially at night or in low-light conditions.

This is more than just a light switch. The board regulates light distribution, ensures consistency in brightness, and integrates with vehicle sensors to automatically adjust based on ambient lighting. In newer models, it is also tied into the car’s onboard computer system, allowing for adaptive behavior and diagnostics.

Think of it as the conductor of a light orchestra, ensuring every note (LED) plays in perfect harmony.

Historical Background: From Incandescent to Intelligent

The idea of backlighting in vehicles dates back to the mid-20th century, when dashboard gauges first began using simple incandescent bulbs. As technology evolved, manufacturers moved to LED-based systems, which offered longer life, less heat, and better energy efficiency.

Mini Cooper, a brand known for its fusion of British charm and German engineering (under BMW), began incorporating advanced backlight circuit boards in the early 2000s to enhance user experience and cabin ergonomics.

Over time, these boards became smarter—integrated with sensors, programmed for mood lighting, and eventually included in infotainment systems. The circuit board’s role expanded from utility to aesthetic to interactive.

There’s plenty more where that came from—browse our other helpful content!

Real-World Applications: Beyond the Dashboard

Though it seems like a niche component, the Mini Cooper backlight circuit board offers a case study in broader technological applications:

1. Automotive Design

This PCB is crucial in modern car design where user interface and ergonomics intersect. Customizable backlighting helps reduce eye strain, enhances aesthetic appeal, and supports branding.

2. Human-Machine Interaction (HMI)

Backlight boards exemplify how technology can be subtle yet powerful in shaping user interaction. They pave the way for more responsive, adaptive in-vehicle experiences.

3. IoT and Smart Devices

The principles behind adaptive lighting and minimal energy consumption are mirrored in IoT devices—from smart thermostats to wearable tech.

4. Aerospace and Defense

In cockpit design, similar backlight boards ensure pilots can see controls in low-light environments without compromising night vision.

5. Healthcare Equipment

High-precision medical devices use similar boards for intuitive interfaces that minimize user error, even in high-stress environments.

Comparison: Mini Cooper vs. Traditional Lighting Systems

| Feature | Mini Cooper Backlight Circuit Board | Traditional Vehicle Lighting |

|---|---|---|

| Light Source | LED, integrated circuit | Incandescent or fluorescent |

| Control System | Microcontroller-based | Manual switch or basic dimmer |

| Adaptability | Responsive to ambient light and driving mode | Static |

| Power Efficiency | High | Moderate to Low |

| Aesthetics | Customizable color and intensity | Limited options |

Where traditional lighting is reactive and limited, the Mini Cooper system is proactive, adaptive, and part of a larger intelligent ecosystem.

Future Implications: Ethics, Risks, and Opportunities

As vehicles become more digital, every component—no matter how small—has the potential to collect data, interact with other systems, and shape driver behavior.

Opportunities:

-

Enhanced personalization (e.g., mood lighting based on biometrics)

-

Integration with AI-based systems for predictive adjustments

-

Sustainability through low-power, recyclable PCBs

Risks:

-

Over-dependence on automated systems

-

Increased repair costs due to complex electronics

-

Data privacy concerns if lighting behavior is tracked or logged

Ethical Considerations:

Should backlighting change based on a driver’s mood or stress levels? Could certain colors increase aggression or reduce focus? As HMI becomes more immersive, these are no longer sci-fi hypotheticals—they’re real design questions.

Best Practices: Designing for Automotive Backlight Systems

Whether you’re an engineer or a tech hobbyist, designing or repairing these systems requires precision. Here are some key principles:

1. Use High-Quality LED Components

Ensure brightness uniformity and long lifespan. Automotive environments are harsh—your components need to be resilient.

2. Prioritize PCB Layout

Isolate power and signal paths to reduce interference. Use thermal vias to manage heat.

3. Incorporate Light Sensors

Allow real-time adjustment to ambient conditions for both safety and comfort.

4. Ensure Fail-Safe Operation

If the lighting system fails, drivers should still have minimal visibility of key functions.

5. Test for Vibration and Shock

Road conditions can be unpredictable. Your design should hold up under stress.

Conclusion: Light as a Language of Innovation

What we see as a soft dashboard glow is actually a powerful dialogue between machine and driver. The Mini Cooper backlight circuit board is not just a utility—it is a testament to modern craftsmanship and technological subtlety.

In an age of flashy tech headlines, sometimes the most profound innovations are the quietest ones. Like neural pathways lighting up with purpose, these boards create not just visibility—but meaning. They allow us to connect with our machines in ways that are safe, beautiful, and deeply human.

Loved this post? You’ll find even more just like it on our blog!

FAQs

1. What is the Mini Cooper backlight circuit board?

It’s a tiny circuit board that controls the lights behind buttons, dials, and displays in your Mini Cooper.

2. Why is it important?

It helps you see and interact with your car’s controls safely, especially at night.

3. Can it be replaced or repaired?

Yes, but it requires expertise in car electronics. Some newer models may need full panel replacements.

4. Is it the same in all Mini Coopers?

No, newer models have more advanced boards with added features like color customization and auto-adjust lighting.

5. What happens if it fails?

You might not see dashboard lights properly. It doesn’t affect driving, but it impacts visibility and comfort.